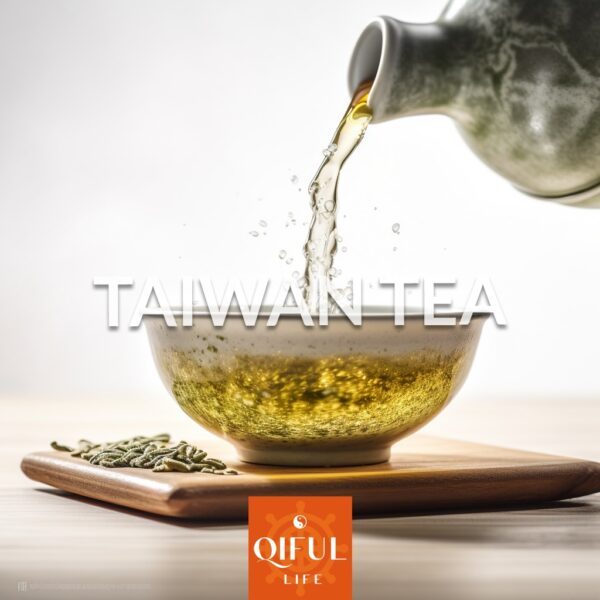

A Guide to Oolong Tea Production

Oolong tea production spans over 300 years. In the 18th century, Fujian province developed Oolong tea, initially attributed to the loyal family or emperor. Its distinct flavor and fewer restrictions led to its popularity and spread to other provinces and countries. Fujian’s favorable climate, with ample water and sunshine, supports ideal tea cultivation. The tea industry in Fujian, including Oolong tea, significantly contributes to the local economy, generating billions of dollars annually.

Local residents in Fujian prefer Oolong tea, sometimes calling it “Kongfu tea.” This name highlights that appreciating Oolong is an art requiring time to savor, not referring to martial arts.

Oolong Tea Production Steps

Oolong Tea is processed using 5 steps:

- Plucking

- Withering

- Squeezing

- Stir Fixation

- Rolling

Plucking

Pluck one bud and 3-4 leaves during early spring. Prefer leaves plucked between noon and 4 pm, as reduced water content from sun evaporation helps preserve flavor.

Withering and Fermentation

Wither the plucked leaves in the sun to activate enzymes. As water evaporates, the leaves become pliable. Oolong tea is unique for its simultaneous withering and fermentation, resulting in a half-fermented tea with the fresh flavor of green tea and the mellow aftertaste of black tea.

Squeezing

Place withered leaves in a squeezing machine to start enzymatic oxidation. This step oxidizes the leaves, making them harder and changing their color to yellow.

Stir Fixation

Spread the tea leaves on the floor to cool down. The leaves soften again and their edges turn red. This step helps release the tea’s essence gained during squeezing.

Rolling

Shape the softened leaves into small, wrinkled strips for storage or delivery. Different regions use various drying methods, with sunshine drying being common. Sunshine drying preserves the tea’s distinct flavor through spontaneous fermentation.

Handmade vs. Machine-Made

The tea industry in Fujian uses both modern and traditional techniques. Small workshops and large factories coexist. Novice tea drinkers might not notice a significant difference between hand and machine-made tea, but some consumers prefer handmade varieties. The way you drink and appreciate the tea can be as important as the tea itself.

Where is Oolong Produced?

The main areas of Oolong production in the world are Fujian Province and Taiwan.